Custom 310s Stainless Steel Sintering Belts - Leading Exporters & Manufacturer Info

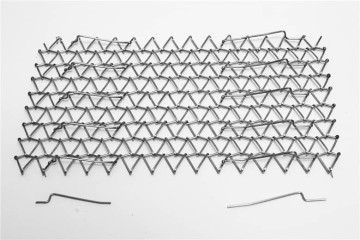

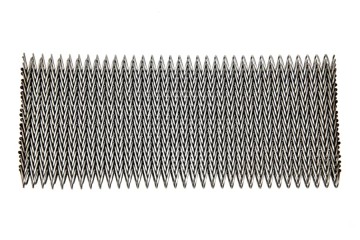

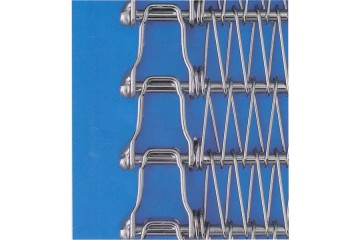

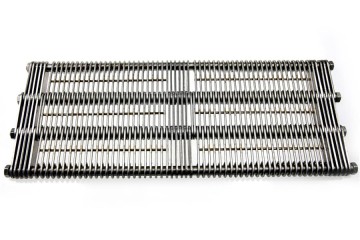

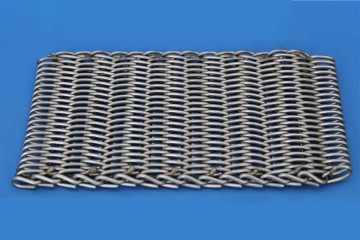

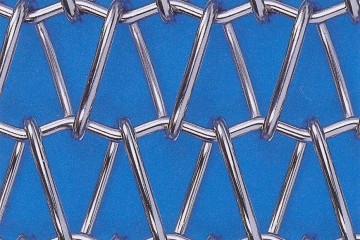

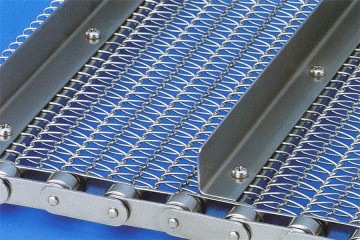

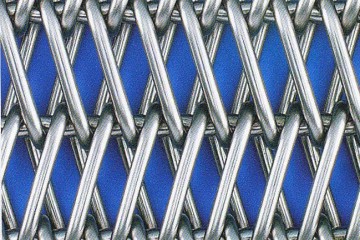

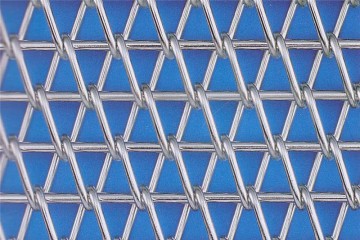

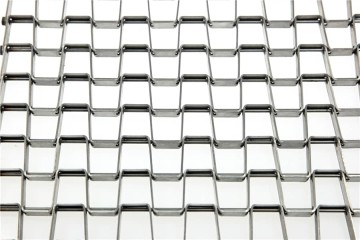

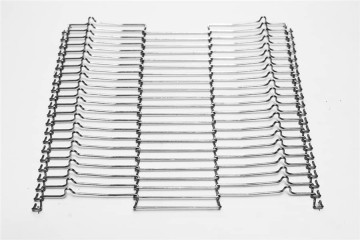

When sourcing the ideal 310s Stainless Steel Sintering Belt, quality and reliability are paramount. This belt is specifically engineered for high-temperature applications, making it suitable for various industries that demand durable and efficient solutions. The sintering process requires a belt capable of withstanding extreme conditions, and the 310s stainless steel provides exceptional oxidation resistance and strength. JIANGSU HUADA Metal Mesh BELT CO., LTD. distinguishes itself among suppliers, upholding high standards and longevity in their sintering belts. Partnering with them ensures the ability to meet clients' needs effectively, allowing for the provision of top-quality products while enhancing operational efficiency. Enhance your production line with a premium 310s Stainless Steel Sintering Belt designed for optimal performance.Practical Methods To 310s Stainless Steel Sintering Belt Stands Out Ahead of the Curve

As the global demand for advanced Material Handling solutions continues to rise, JIANGSU HUADA METAL MESH BELT CO., LTD. stands at the forefront with our innovative 310s stainless steel sintering belts. These belts not only offer significant durability and resistance to extreme temperatures but also provide efficient operational benefits tailored for various industries. Our commitment to precision engineering and quality is evident in our ISO 9001 and CE certified production facilities, ensuring that each belt meets the highest standards of reliability and performance. The unique characteristics of 310s stainless steel make our sintering belts an ideal choice for tasks that demand consistent thermal stability and strength. Unlike conventional belts, our sintering solutions are designed to withstand harsh environments while maintaining their structural integrity. This quality is particularly beneficial for industries like food processing, ceramics, and metalworking, where efficiency and safety are paramount. By adopting these advanced belt systems, global buyers can achieve not only improved productivity but also a competitive edge in their respective markets. Partnering with HUADA means choosing a manufacturer with over a decade of experience supplying more than 20 countries across five continents. We understand the unique challenges faced by our clients and are dedicated to providing tailored solutions that meet their specific needs. Let us help you elevate your operations with our cutting-edge sintering belts, and join the ranks of satisfied customers reaping the benefits of our innovative technologies.

Practical Methods To 310s Stainless Steel Sintering Belt Stands Out Ahead of the Curve

| Property | Value | Importance |

|---|---|---|

| Chemical Composition | Cr: 24%, Ni: 19%, Mo: 0.15% | High corrosion resistance |

| Melting Point | 1400-1450°C | Good for high-temperature applications |

| Density | 8.0 g/cm³ | Strength and durability |

| Sintering Temperature | 1250°C | Optimum for particle bonding |

| Yield Strength | 290 MPa | Ensures structural integrity |

| Ultimate Tensile Strength | 600 MPa | Key for mechanical applications |

| Corrosion Resistance | Excellent in various environments | Longevity of product life |

How To Identify 310s Stainless Steel Sintering Belt Your Trusted OEM Partner Market Leader

C

Christopher Lewis

I am highly satisfied with the quality. The customer service showed great expertise in handling my requests.

27 June 2025

D

Daniel Clark

This item is built to last! The professionalism of the customer service is truly impressive.

15 May 2025

B

Barbara Jackson

Impressive product durability! The professionalism of the service team made all the difference.

09 May 2025

J

Jessica Thompson

Fantastic product! The professionalism of the support staff adds great value to the experience.

11 June 2025

S

Samantha Wilson

What an amazing find! The product quality is incredible, and the support team is very helpful.

01 June 2025

L

Linda Green

The quality is unmatched! I appreciate the professionalism of the customer service team.

20 May 2025